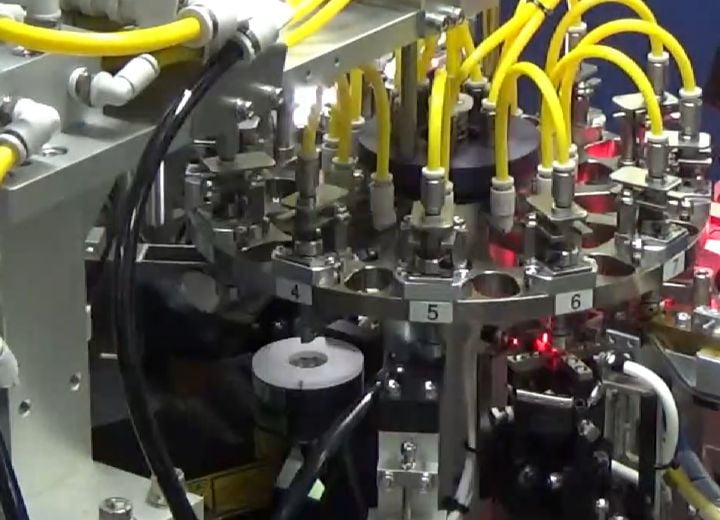

NCT-5100 series

Multi-function taping handler

NCT-5100 series

Supply method according to customer's request for

example, it is possible to use various supply methods

as well as parts feeders.

It is an automatic taping handler that can perform

electrical characteristic inspection and visual

inspection of chip parts and tape only non-defective

products.

Features of high-speed embossing taping handler

Image inspection of electronic components inserted in

the carrier tape is possible from the top surface before

sealing the cover tape.

Visual inspection is possible by adding image

processing in the index.

The NCT-5100 can support the automatic replacement function(auto-reject function) when the

in-tape image inspection is defective.

Product Videos

Basic specifications

| Applicable device | Various chip device |

|---|---|

| Embossed carrier tape width | 8.0 , 12.0 , 16.0[mm] |

| Reel diameter | Supply side maximum φ700 [mm] Winding side φ330 [mm] |

| Parts supply | Parts feeder |

| Cycle time | Fastest 0.1 [seconds / piece] |

| Power supply | Single-phase AC200 [V], AC220 [V] AC230 [V] 50/60 [Hz] (transformer tap changer) |

| External dimensions | W880×H1,620×D690[mm] |

| Touch screen Supports languages |

Japanese, English, Chinese, Korean |

| Option | ・ Visual inspection function ・ In-tape image inspection function ・ Electrical characteristics function ・ Classification function (Up to 10 classifications) ・ SUB INDEX function ・ Auto-reject function ・ Variable supply function |

number of measurement items, etc., so we will make a decision after consultation.

* The photos shown are for illustrative purposes only.

Please note that the actual color may differ due to shooting and printing.

Taping handler lineup

High-speed taping handler

NCT-2800 series

It is a taping handler that aims to handle

packaging at high speed.

Reel taping handler

NCT-8000 series

It is a taping handler for the purpose of

inspection again after packaging.

Tray taping handler

NCT-6300T serise

It is a structured device that can add image inspection, electrical inspection, and optical system inspection.

CONTACT

For document requests and inquiries, please contact us using the email form below or by phone.

Click here for inquiries by phone

+81-428-31-8211